Right now, we're witnessing significant structural shifts in the global economy. These profound economic transformations are poised to impact nearly every aspect of our lives, from business operations to personal interactions, and even beyond.

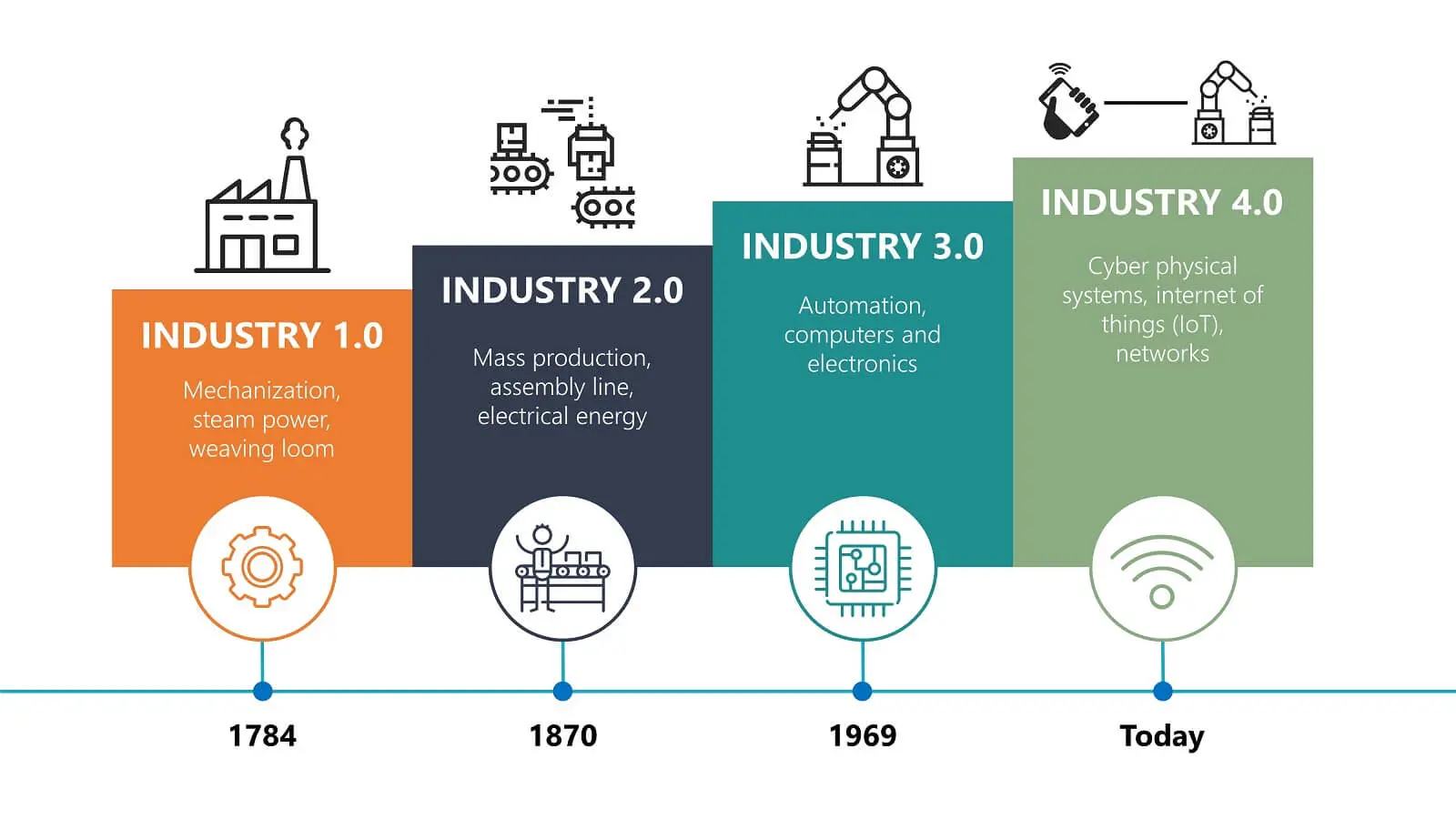

At the forefront of these changes is Industry 4.0, the Fourth Industrial Revolution, which marks a period of rapid technological innovation. This transformative era is characterized by the integration of digital technologies across every aspect of business, manufacturing, and society. It's a time when smart technologies, automation, and data-driven insights are converging to revolutionize how industries operate.

The technologies leading this evolution are filled with endless potential. From artificial intelligence and robotics to the Internet of Things (IoT) and big data analytics, these innovations are reshaping manufacturing processes, supply chains, and business strategies. As we dive deeper into this exciting subject, we’ll explore how Industry 4.0 technologies are driving business transformation and offering new avenues for efficiency, sustainability, and competitive advantage.

What is Industry 4.0?

The term "Industry 4.0" is closely tied to the evolving industrial landscape and represents a pivotal phase in the Fourth Industrial Revolution. This revolution is fundamentally transforming production systems, leveraging automation technologies and robotics to create highly efficient, smart manufacturing environments. With cutting-edge technological innovations making their way into factories and industrial plants, businesses are experiencing a remarkable shift. The competition now revolves around who can best harness the power of these advanced technologies to gain a competitive edge. It’s an exhilarating time to be involved in this technological evolution!

In essence, we’re discussing a strategic roadmap for advancing the high-tech industry by adopting smart manufacturing practices. In today’s hyper-competitive landscape, a company’s success is increasingly defined by its ability to improve the autonomy and self-sufficiency of its production processes, all while integrating robotic automation and AI-driven systems to drive efficiency and innovation.

The gap between companies that embrace Industry 4.0 technologies and those that resist adoption is as stark as the difference between using modern computing tools versus relying on traditional, outdated methods like the abacus. Companies that leverage digital transformation are miles ahead, while those that don’t risk falling behind in a rapidly evolving marketplace.

Core Advantages of Implementing Industry 4.0 Technologies:

- Enhanced Enterprise Productivity: By implementing automated systems, robotic solutions, and AI-driven workflows, businesses can achieve higher levels of productivity while minimizing the need for manual intervention. This directly impacts operational efficiency and throughput in production lines.

- Reduction in Production Costs: With the help of smart manufacturing technologies, companies can significantly lower their production costs by reducing waste, streamlining processes, and automating tasks that were previously labor-intensive. Predictive maintenance, powered by IoT sensors, further reduces costly machine breakdowns and downtimes.

- Process Optimization & Downtime Minimization: Industry 4.0 technologies enable businesses to optimize production processes by utilizing real-time data analytics. Through machine learning algorithms and AI-based systems, businesses can continuously fine-tune their operations, reducing downtime and enhancing overall system reliability.

- Competitive Growth in the Market: Digital transformation through robotics, AI, and cloud computing allows companies to be more agile, responsive to market trends, and capable of scaling faster than ever before. These technologies provide businesses with a competitive advantage that leads to sustained growth and market leadership.

- Easier Product Experimentation & Prototype Testing: Thanks to additive manufacturing (3D printing) and flexible production systems, companies can now rapidly experiment with new products, test prototypes, and make quick adjustments to meet market demands without the high costs associated with traditional manufacturing methods.

- Sophisticated & Efficient Final Products: Through the integration of advanced technologies like robotic automation, data analytics, and AI, the final product becomes more sophisticated, customized, and efficient. Companies can offer tailored solutions at scale, improving customer satisfaction while reducing costs.

How to Implement Predictive Maintenance Using IoT Devices

Predictive maintenance (PdM) powered by IoT (Internet of Things) is transforming the way industries manage equipment health. Instead of relying on fixed schedules or reacting to breakdowns, predictive maintenance lets businesses anticipate issues before they happen—saving money, reducing downtime, and extending asset life.

Step-by-Step Guide to Implementing Predictive Maintenance with IoT

1. Identify Critical Equipment

Start by selecting high-value or high-risk machinery. Think compressors, motors, turbines, or HVAC systems—anything where failure causes major downtime or safety concerns.

2. Choose the Right IoT Sensors

Install IoT-enabled sensors to track data like:

- Vibration

- Temperature

- Humidity

- Pressure

- Power consumption

- RPM

These sensors continuously collect real-time performance data.

3. Connect Sensors to an IoT Platform

Use edge devices or gateways to transfer sensor data to a centralized IoT platform via Wi-Fi, LoRa, 5G, or other protocols. Cloud-based platforms like AWS IoT, Azure IoT Hub, or Siemens MindSphere are popular choices.

4. Data Aggregation and Preprocessing

Clean, normalize, and format the incoming data. Remove noise, fill gaps, and segment data for specific components. This ensures quality input for predictive models.

5. Apply Machine Learning Algorithms

Use machine learning or AI to detect patterns and anomalies. Common algorithms include:

- Regression (for time-to-failure prediction)

- Decision Trees

- Random Forest

- K-Means Clustering (for grouping abnormal behavior)

- Neural Networks

Train the model using historical data, then deploy it for real-time predictions.

6. Trigger Alerts and Maintenance Workflows

Set thresholds and configure automated alerts when unusual patterns are detected. These can trigger maintenance tickets in your CMMS (Computerized Maintenance Management System) or notify your operations team.

7. Analyze and Improve Continuously

Predictive models get smarter over time. Use feedback loops from actual maintenance logs to refine the algorithm and improve accuracy.

Smart factory is impossible without the Internet of Things(IoT). Sensors and gauges connect to IoT platforms that analyze incoming data. The analysis results become the basis used to further plan the work of systems and the operation of individual elements which are parts of those systems

How to Choose the Right IoT Devices for Your Factory

Choosing the right IoT devices for your factory isn’t just about buying sensors—it’s about building a connected ecosystem that improves efficiency, reduces downtime, and supports smart decision-making. But with hundreds of options and industrial protocols out there, how do you know what’s right for your needs?

Here’s a practical, step-by-step guide to choosing the right IoT devices for your factory floor.

1. Start With Your Business Goals

Don't start with tech—start with strategy.

Ask:

- Do you want to reduce unplanned downtime?

- Are you aiming to improve energy efficiency?

- Is predictive maintenance a priority?

- Do you need real-time production visibility?

Your objectives determine the types of IoT devices you need—e.g., vibration sensors for maintenance, smart meters for energy tracking, or flow sensors for fluid management.

2. Identify Key Assets and Processes

Map out your critical equipment, systems, and workflows. This helps pinpoint where you can extract meaningful data.

Examples:

- Motors → Vibration, temperature sensors

- Conveyors → Proximity, RPM sensors

- Boilers → Pressure and heat sensors

- Production lines → Smart cameras, PLC integration

3. Match Devices With Data Needs

Choose devices based on what data you need to capture:

| Data Type | Suggested IoT Device |

|---|---|

| Vibration | MEMS or piezoelectric vibration sensors |

| Temperature | Industrial-grade thermal sensors |

| Humidity | Hygrometers with Modbus support |

| Position/Speed | Rotary encoders, proximity sensors |

| Energy Usage | Smart energy meters with MQTT/Modbus |

| Visual QA | Smart cameras with AI/ML capability |

✅ Look for industrial-grade, IP-rated, ruggedized devices suited to harsh factory conditions.

4. Check Compatibility with Your Existing Systems

You want devices that “speak the same language” as your current infrastructure.

Ask:

- Does the sensor support Modbus, OPC UA, MQTT, or EtherNet/IP?

- Can it integrate with your PLC, SCADA, or MES system?

- Will it work with your existing cloud or edge platform?

Fieldbus gateways or edge controllers can help bridge protocol gaps if needed.

5. Evaluate Security Features

Security is non-negotiable. Choose devices with:

- Secure boot and firmware

- Data encryption (TLS/SSL)

- Certificate-based authentication

- OTA (Over-the-Air) update support

6. Think About Scalability and Interoperability

You don’t want devices that will bottleneck your digital transformation later.

Look for:

- Plug-and-play compatibility

- API or SDK support

- Modular designs that allow expansion

7. Balance Cost with Value

Cheaper isn’t always better—especially in an industrial setting. Consider:

- Long-term ROI from improved uptime

- Maintenance costs

- Device lifespan and ruggedness

Our company specializes in consulting, product development, and customer support. We tailor our services to fit the unique needs of businesses across various sectors, helping them grow and succeed in a competitive market.

You can reach our customer support team by emailing info@yourcompany.example.com, calling +1 555-555-5556, or using the live chat on our website. Our dedicated team is available 24/7 to assist with any inquiries or issues.

We’re committed to providing prompt and effective solutions to ensure your satisfaction.

We offer a 30-day return policy for all products. Items must be in their original condition, unused, and include the receipt or proof of purchase. Refunds are processed within 5-7 business days of receiving the returned item.

We offer a 30-day return policy for all products. Items must be in their original condition, unused, and include the receipt or proof of purchase. Refunds are processed within 5-7 business days of receiving the returned item.

We offer a 30-day return policy for all products. Items must be in their original condition, unused, and include the receipt or proof of purchase. Refunds are processed within 5-7 business days of receiving the returned item.

We offer a 30-day return policy for all products. Items must be in their original condition, unused, and include the receipt or proof of purchase. Refunds are processed within 5-7 business days of receiving the returned item.

We offer a 30-day return policy for all products. Items must be in their original condition, unused, and include the receipt or proof of purchase. Refunds are processed within 5-7 business days of receiving the returned item.