Write

HART Gateways- Connect your HART Field Devices to Your Industrial Control System

something...

What is a HART Gateway

A HART gateway acts as a HART protocol converter, translating HART communication into industrial Ethernet protocols like Modbus TCP, EtherNet/IP, PROFINET, or OPC UA. This means your existing control system can communicate with HART smart transmitters, valve positioners, and other intelligent field devices without needing specialized HART interface cards.

Think of it as a translator that speaks both languages—HART on one side, your network protocol on the other. The gateway polls your HART devices, collects process variables and diagnostic information, then makes that data available to your control system in real-time.

What we propose to our customers

Request for HART Gateway Quote contact us for sales & Services Request a Quote

Choosing the Right HART Gateway for Your Application

For Process Automation

If you're running a chemical plant, refinery, or other process facility, look for gateways that support full HART variable mapping. You'll want access to all four HART variables (PV, SV, TV, QV) plus status and diagnostic information.

For Management systems

Integrating with AMS or other device management software? Choose a gateway with robust HART DDL (Device Description Language) support and full HART command set implementation.

For Retrofit Projects

Upgrading an older system? HART protocol gateways with universal HART device support work with any manufacturer's HART-compliant instruments—no proprietary limitations.

For Critical Application

Need redundant HART gateway configurations? Look for models supporting failover and redundancy features to ensure continuous data availability.

Key Features of Industrial HART Gateways

Multi-Channel HART Interface

Connect multiple HART devices simultaneously—typically 8, 16, or 32 channels depending on the model. Each channel operates independently, polling HART instruments at configurable intervals.

Wireless HART Gateway Support

Some models include Wireless HART gateway capabilities, letting you integrate both wired and wireless HART devices into a single network infrastructure.

Protocol Flexibility

Modern HART communication gateways support multiple industrial protocols:

Modbus TCP HART gateway configurations

Ethernet/IP to HART connectivity

PROFINET HART gateway integration

OPC UA server functionality

HART-IP Support

Advanced models offer HART-IP gateway capabilities, providing direct IP connectivity for HART devices using the standardized HART-IP protocol.

Real-World Industrial Applications of HART Modules

About our Product line

I-7570 / 7567 / 7547

Serial / USB / Ethernet - to HART converter

I-7570 is a Serial / USB to HART converter and can be configured as a HART master with HC_Tool utility or a HART slave with HDS utility.

As a HART master, It allows users to access the HART slave by using RS-232 / RS-422 / RS-485. These HART slave devices may be a transmitter, actuator, current output device and so forth. In addition, by using the I-7570 utility tool, users can configure module and test HART communication easily and quickly.

As a HART Slave, It can be used to simulate multi HART slave devices simultaneously to exchange data with HART master device by using ICP DAS HART converter (like: I-7567 / I-7570 / I-7547) connected to any COM port (USB / 232 / 485 / Ethernet). By this way, users can develop or verify the HART master program without any HART slave device.

- Support HART Short / Long frame

- Support HART Burst mode

- Support point-to-point or multi-drop HART mode

- Support connecting up to 15 HART slave devices

- Allow two HART masters

- Provide utility tool for module configuration and HART communication

- 4KV ESD Protection

- Built-in Watchdog

- Selectable 250Ω load resistor

- Support HART OPC Server provided by HART Foundation.

Application:

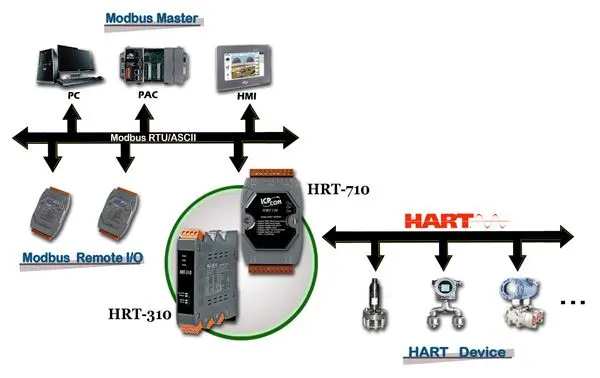

HRT-710

Modbus RTU/ASCII to HART Gateway

The HRT-710 Gateway is specially designed for the master device of HART protocol. It allows the Modbus master to access the HART devices. These HART devices may be a transmitter, an actuator and so forth. In addition, we also provide the software utility, HG_Tool, for module configuration and HART device diagnosis. By using these modules, users can integrate their HART devices into Modbus network easily and quickly.

HRT-710, a HART master to Modbus slave gateway, is applied to integrate

the information from these HART flow meters into the customer's HMI

system. Through the HRT-710, all of the HART flow meters will be

regarded as Modbus slave devices and the HMI system can use the built-in

Modbus RTU communication to access these HART flow meters easily.

- Support HART Short/Long frame

- Support HART Burst mode

- Allow two HART Masters

- Working in point-to-point or multi-drop HART mode

- Connecting up to 15 HART modules

- Support Modbus RTU and ASCII format

- Support Modbus Slave mode

- Support firmware update via Com Port

- Support on-line replacement of HART devices

- Support acquire Long Frame Address automatically

- Provide LED indicators

- Built-in Watchdog

- DIN Rail or Wall Mounting

Application:

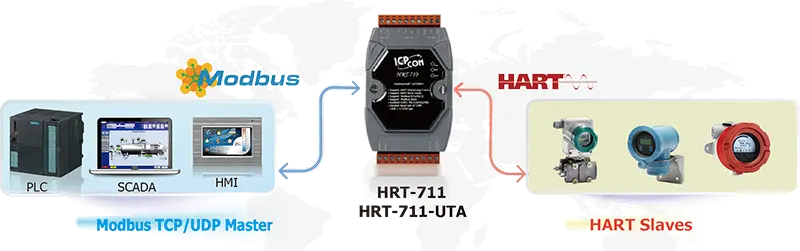

HRT-711

Modbus TCP/UDP to HART Gateway

The HRT-711 Gateway is specially designed for the master device of HART

protocol. It allows the Modbus master to access the HART devices. These

HART devices may be a transmitter, an actuator and so forth. In

addition, we also provide the utility software for users to configure

the HRT-711. By using this module, users can integrate their HART

devices into Modbus network easily.

- Support HART Short/Long frame

- Support HART Burst mode

- Allow two HART Masters

- Working in point-to-point or multi-drop HART mode

- Connecting up to 15 HART modules

- Support Modbus TCP/UDP server

- Support Modbus Slave mode

- Support firmware update via Com Port

- Support on-line replacement of HART devices

- Support acquire Long Frame Address automatically

- Provide LED indicators

- Built-in Watchdog

- Mountable on DIN Rail

Application:

Frequently asked questions

Here are some common questions about our HART Gateways.

HART devices that can connect to a single gateway depends mainly on the gateway model, communication type, and network configuration.

Typpically, a wired HART gateway can support 8 to 64 HART devices, depending on how many HART I/O channels or multiplexers it has. For WirelessHART gateways, a single gateway typically supports 50 to 250+ field devices, with high-end industrial gateways handling even more when the network is properly designed.

Factors such as polling speed, update rate, burst mode usage, and network traffic also affect the practical device limit. To ensure reliable communication and performance, manufacturers usually recommend staying slightly below the maximum supported device count per gateway.

In most cases, you do need software to configure a HART gateway, but it’s usually standard, vendor-provided, and easy to use.

Typically, HART gateways are configured using web-based interfaces, device management software, or HART host tools that run on a PC. These tools allow you to set up device polling, map HART variables, configure communication protocols (like Modbus, OPC UA, or Ethernet/IP), and monitor diagnostics.

The good news is that you usually don’t need custom programming—most configurations are done through graphical dashboards. Once set up, the gateway runs independently, making ongoing maintenance simple and user-friendly.

Yes, HART gateways generally work with devices from any manufacturer, as long as those devices comply with the HART communication standard.

HART is an open, globally recognized protocol, so transmitters, sensors, and actuators from different vendors can communicate through the same gateway. Most gateways automatically detect HART devices and read standard parameters such as process variables, status, and diagnostics. This makes them ideal for multi-vendor environments where plants use instrumentation from several suppliers.

The minimum loop current for HART communication is typically 4 mA, which aligns with the standard 4–20 mA analog signal used in industrial instrumentation.

HART works by superimposing a digital signal on top of the analog current loop, so the loop must be powered and stable—usually at 4 mA or higher—for reliable communication. In addition to current, the loop also needs a minimum load resistance of about 230 ohms to properly detect the HART signal.

The polling speed of a HART gateway depends on several factors, including the HART protocol version, number of connected devices, loop conditions, and gateway processing power.

In general, a HART gateway can poll a single device in about 0.5 to 2 seconds for basic variables and status information. When multiple devices are connected, the gateway typically polls them sequentially, so the total update time increases as more devices are added. Advanced data requests, diagnostics, or configuration reads can take slightly longer.

The HART protocol works with Ethernet by using a HART gateway or HART-to-Ethernet converter that bridges traditional field devices with modern industrial networks.

At the field level, HART communicates over a 4–20 mA analog loop with a superimposed digital signal. The HART gateway reads this digital data—such as process variables, device status, and diagnostics—and then converts it into Ethernet-based protocols like Modbus TCP, OPC UA, PROFINET, EtherNet/IP, or MQTT. Once converted, the data can be transmitted over standard Ethernet networks to PLCs, SCADA systems, historians, or cloud platforms.

This setup allows legacy HART instruments to participate in Industrial Ethernet and IIoT architectures without changing existing wiring. It enables real-time monitoring, remote device management, predictive maintenance, and seamless integration with enterprise and cloud systems, making HART a key enabler for digital transformation in industrial automation.

HART point-to-point mode uses one device per 4–20 mA loop, where the analog signal represents the process value and digital HART data is used for configuration and diagnostics.

HART multi-drop mode connects multiple devices on the same loop using digital communication only, with the loop current fixed (typically at 4 mA).