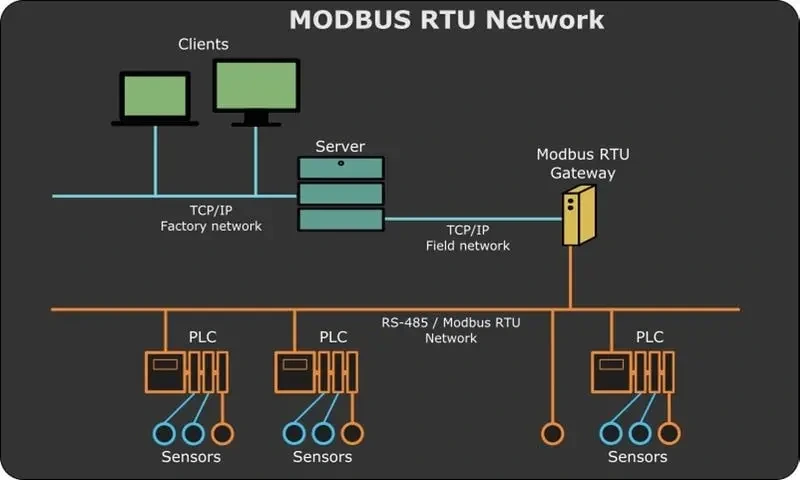

Modbus Gateway -Modbus is the most common Industrial protocol and most PLC, Controllers, and industrial software can communicate via this protocol.

What is a Modbus Gateway?

A Modbus Gateway enables seamless PLC communication and device connectivity by linking serial devices with Industrial Ethernet in modern industrial automation systems. It supports SCADA systems, HMI integration, and data acquisition systems for reliable supervisory control and process automation. As an Industrial IoT gateway, it also enables remote monitoring, OPC UA integration, and edge computing for smarter factory and building automation.

What we propose to our customers

Request for MODBUS Gateway Quote contact us for sales & Services Request a Quote

Choosing the Right Modbus Gateway for Your Application

Modbus TCP to RTU Gateway

Converts between Modbus TCP (Ethernet-based) and Modbus RTU (serial-based). This is probably the most common type you'll encounter. It's perfect for bringing serial devices onto your plant network.

Modbus to Ethernet Gateway

Allows serial Modbus devices to communicate over standard Ethernet infrastructure. This simplifies your industrial communication network and often reduces wiring costs.

Protocol Converter Gateway

Surpasses Modbus by transforming multiple industrial protocols. These tools are adaptable for complex automation systems.

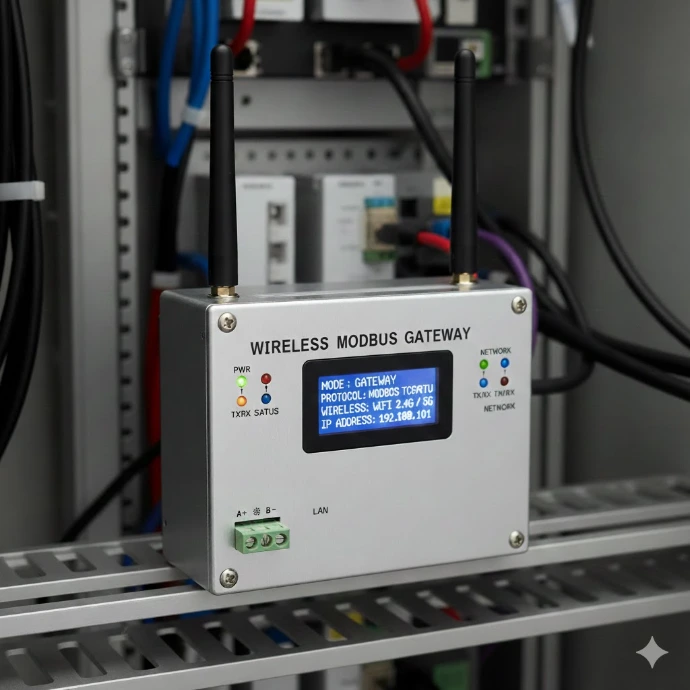

Wireless Modbus Gateway

Provides wireless connectivity for Modbus devices, eliminating cable runs in difficult installations. Particularly useful for remote monitoring applications or retrofit projects.

Key Features of Industrial Modbus Gateways

Number of devices

How many Modbus slaves do you need to connect? Some gateways support just a handful, while others can handle hundreds of devices simultaneously.

Communication speed

Your baud rate requirements matter. Most modern gateways handle standard speeds, but high-speed applications need careful consideration.

Environmental conditions

Industrial environments can be harsh. Look for gateways with appropriate IP ratings, temperature ranges, and vibration resistance for your specific application.

Power supply options

Will you need PoE capability, or do you have industrial power supplies available? Some gateways offer flexible power input options.

Real-World Industrial Applications of Modbus Gateway

About our Product line

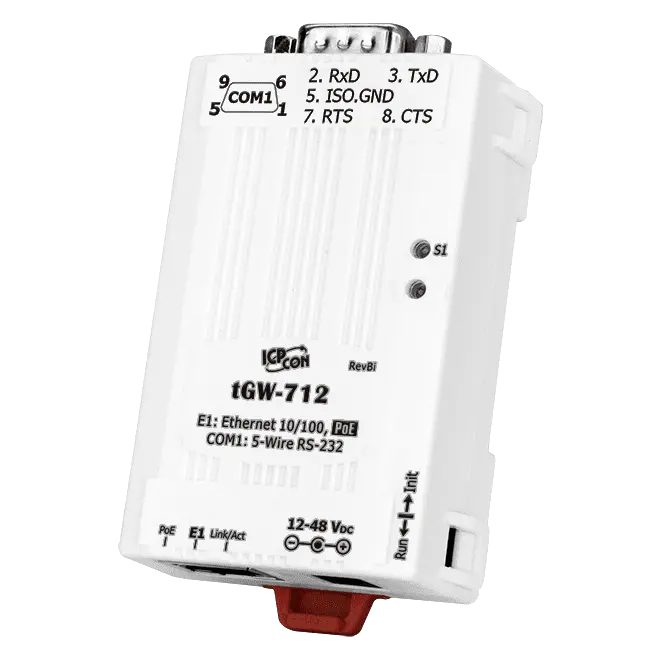

tgw-712

Tiny Modbus TCP to RTU/ASCII Gateway with PoE and 1-port RS-232 (DB-9 Male Connector)

The tGW-700 is a Modbus TCP to RTU/ASCII gateway that enables a Modbus TCP host to communicate with serial Modbus RTU/ASCII devices through an Ethernet network, and eliminates the cable length limitation of legacy serial communication devices. The module can be used to create a pair-connection application (as well as serial-bridge or serial-tunnel application), and can then route data over TCP/IP between two serial Modbus RTU/ASCII devices, which is useful when connecting mainframe computers, servers or other serial devices that use Modbus RTU/ASCII protocols and do not themselves have Ethernet capability.

- Supports Modbus TCP/UDP master and slave

- Supports Modbus RTU/ASCII master and slave

- Max. TCP connections (masters) per serial port: 32

- Read-cache ensures faster Modbus TCP/UDP response

- Supports UDP responder for device discovery (UDP Search)

- Static IP or DHCP network configuration

- Tiny Web server for configuration (HTTP)

- Male DB-9 connector for easy wiring

- Cost-effective Modbus gateway

Application:

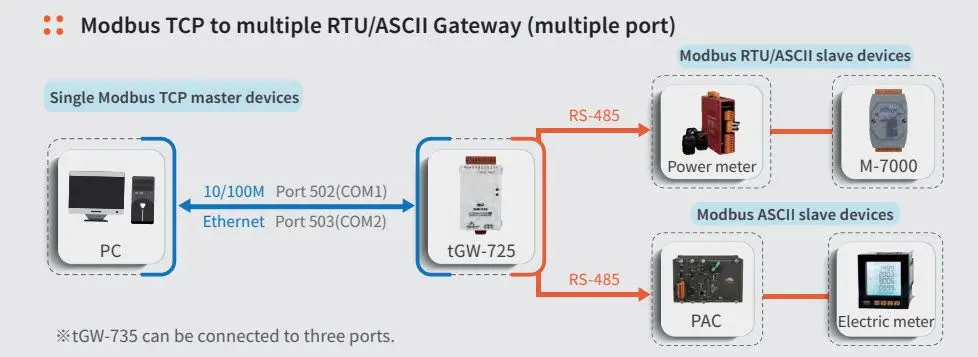

tgw-732

Tiny Modbus TCP to RTU/ASCII Gateway with PoE and 3-port RS-232

The tGW-700 is a Modbus TCP to RTU/ASCII gateway that enables a Modbus TCP host to communicate with serial Modbus RTU/ASCII devices through an Ethernet network, and eliminates the cable length limitation of legacy serial communication devices. The module can be used to create a pair-connection application (as well as serial-bridge or serial-tunnel application), and can then route data over TCP/IP between two serial Modbus RTU/ASCII devices, which is useful when connecting mainframe computers, servers or other serial devices that use Modbus RTU/ASCII protocols and do not themselves have Ethernet capability.

- Supports Modbus TCP/UDP master and slave

- Supports Modbus RTU/ASCII master and slave

- Max. TCP connections (masters) per serial port: 32

- Read-cache ensures faster Modbus TCP/UDP response

- Supports UDP responder for device discovery (UDP Search)

- Static IP or DHCP network configuration

- Tiny Web server for configuration (HTTP)

- Cost-effective Modbus gateway

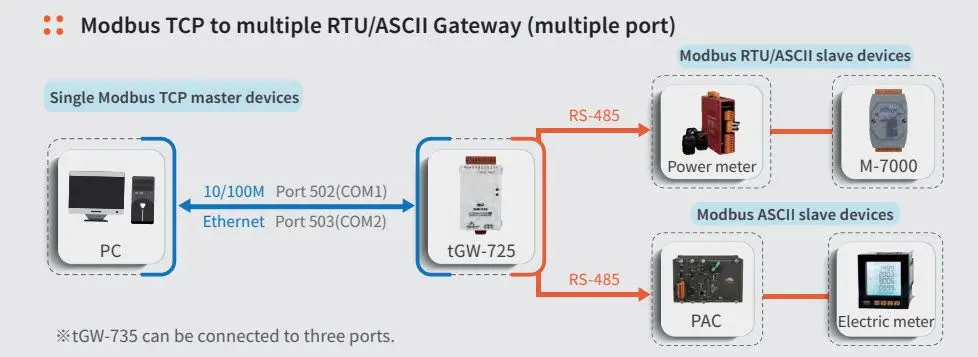

Application:

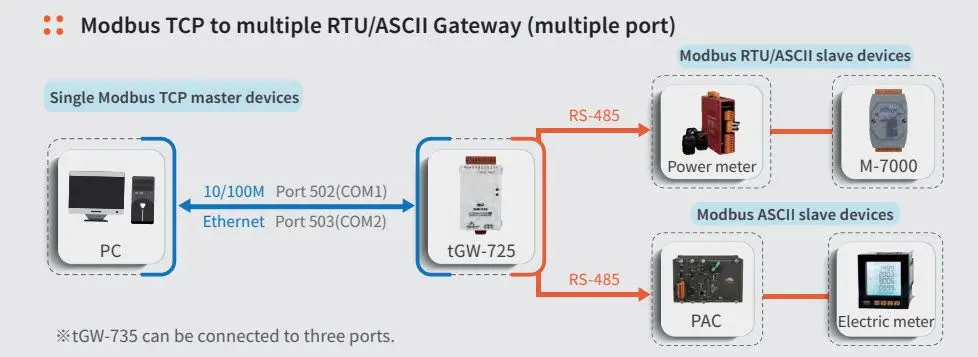

tgw-725

Tiny Modbus TCP to RTU/ASCII Gateway with PoE and 2-port RS-485

The tGW-700 is a Modbus TCP to RTU/ASCII gateway that enables a Modbus TCP host to communicate with serial Modbus RTU/ASCII devices through an Ethernet network, and eliminates the cable length limitation of legacy serial communication devices. The module can be used to create a pair-connection application (as well as serial-bridge or serial-tunnel application), and can then route data over TCP/IP between two serial Modbus RTU/ASCII devices, which is useful when connecting mainframe computers, servers or other serial devices that use Modbus RTU/ASCII protocols and do not themselves have Ethernet capability.

- Supports Modbus TCP/UDP master and slave

- Supports Modbus RTU/ASCII master and slave

- Max. TCP connections (masters) per serial port: 32

- Read-cache ensures faster Modbus TCP/UDP response

- Supports UDP responder for device discovery (UDP Search)

- Static IP or DHCP network configuration

- Tiny Web server for configuration (HTTP)

- Allows automatic RS-485 direction control

- Terminal block connector for easy wiring

- Cost-effective Modbus gateway

Application:

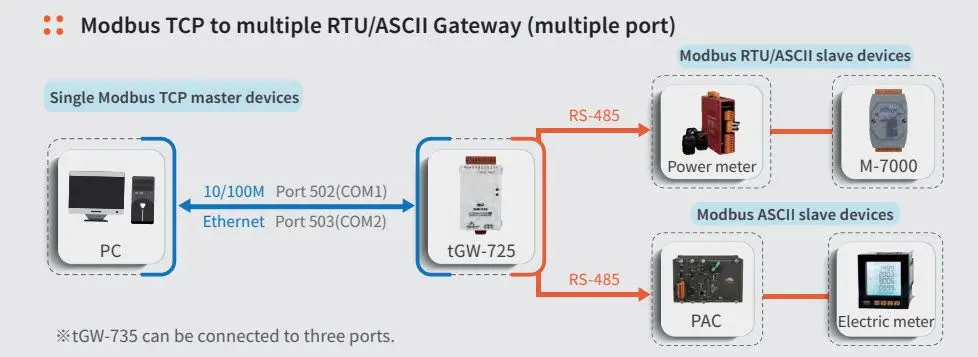

tgw-718

Tiny Modbus TCP to RTU/ASCII Gateway with PoE and 1-port RS-232/422/485

The tGW-700 is a Modbus TCP to RTU/ASCII gateway that enables a Modbus TCP host to communicate with serial Modbus RTU/ASCII devices through an Ethernet network, and eliminates the cable length limitation of legacy serial communication devices. The module can be used to create a pair-connection application (as well as serial-bridge or serial-tunnel application), and can then route data over TCP/IP between two serial Modbus RTU/ASCII devices, which is useful when connecting mainframe computers, servers or other serial devices that use Modbus RTU/ASCII protocols and do not themselves have Ethernet capability.

- Supports Modbus TCP/UDP master and slave

- Supports Modbus RTU/ASCII master and slave

- Max. TCP connections (masters) per serial port: 32

- Read-cache ensures faster Modbus TCP/UDP response

- Supports UDP responder for device discovery (UDP Search)

- Static IP or DHCP network configuration

- Tiny Web server for configuration (HTTP)

- Allows automatic RS-485 direction control

- Terminal block connector for easy wiring

- Cost-effective Modbus gateway

Application:

Frequently asked questions

Here are some common questions about our company.

Yes, Modbus can be connected to Wi-Fi by using a Modbus Wi-Fi gateway or a Wi-Fi IO module. These devices convert Modbus RTU (serial) or Modbus TCP data into wireless communication, allowing easy integration with SCADA systems, PLCs, and Industrial IoT platforms. This setup enables remote monitoring, flexible factory floor connectivity, and reduced wiring in industrial and building automation environments.

The maximum distance for Modbus RTU over RS-485 serial communication is typically up to 1,200 meters (about 4,000 feet) under standard conditions. This distance depends on cable quality, baud rate, proper termination, and network topology. Lower baud rates and correct shielding help maintain reliable communication across long industrial networks.

A Modbus gateway can typically connect up to 247 devices on a Modbus RTU (RS-485) network, since Modbus device addresses range from 1 to 247. The actual number of connected devices depends on factors like baud rate, polling speed, cable length, and network topology. For Modbus TCP, the limit is usually higher and mainly constrained by the gateway’s hardware capacity and network performance.

Modbus itself is not inherently secure, as it was designed for trusted industrial networks and does not include encryption, authentication, or access control. However, it can be made suitable for industrial applications by using secure gateways, network segmentation, firewalls & VPN .When properly secured, Modbus is widely and safely used in SCADA systems, industrial automation, and process control environments

Yes, old (legacy) equipment can be integrated with a new SCADA system using protocol converters and industrial gateways. Devices like Modbus, RS-485, or fieldbus gateways translate legacy serial communication into modern Industrial Ethernet or OPC UA, making the data compatible with current SCADA platforms. This approach enables remote monitoring, data acquisition, and supervisory control without replacing existing machines, reducing cost and downtime.

By supporting multiple industrial protocols and Industrial Ethernet, a Modbus gateway simplifies process automation, data acquisition, and HMI integration. It also enables remote monitoring and Industrial IoT readiness, helping your facility operate more efficiently, securely, and future ready.